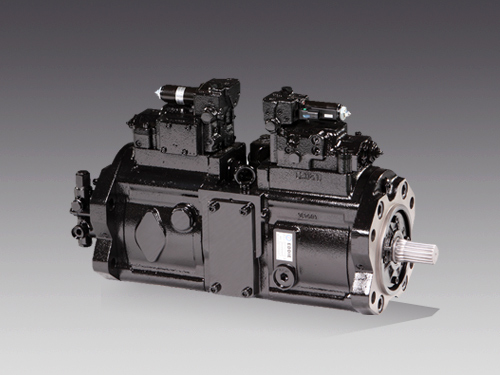

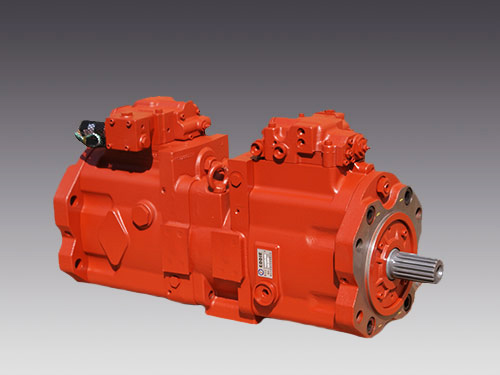

Product Overview

The K3V112DTP-9T8L-14 Hydraulic Piston Main Pump is a critical component designed for a wide range of excavators, ensuring robust and efficient hydraulic power. As a high-performance axial piston pump, it is engineered to meet the demanding requirements of heavy-duty construction and earthmoving machinery. This pump is vital for controlling the precise movements of the excavator's boom, arm, bucket, and tracks, delivering reliable and consistent power for various applications.

Application Scenarios & Case Studies

The K3V112DTP-9T8L-14 hydraulic pump powers excavators in diverse and demanding environments:

Construction Sites:

Excavators equipped with this pump are indispensable for digging foundations, trenching, and grading in commercial and residential construction projects. The pump's precise control allows for accurate excavation, minimizing over-digging and material waste. For instance, on a major urban development, excavators with this pump efficiently laid the groundwork for multi-story buildings, handling thousands of cubic meters of earth daily with consistent performance.

Mining Operations:

In open-pit mining, excavators are used for overburden removal and ore extraction. The pump's high-pressure capabilities ensure that the machine can break through tough rock and move large volumes of material. A case study in a coal mine showed excavators powered by K3V112DTP series pumps maintaining continuous operation in dusty and high-stress conditions, significantly contributing to daily production targets due to their reliability and power.

Demolition & Waste Management:

For demolishing structures and handling large volumes of debris, excavators require strong and responsive hydraulics. This pump provides the necessary power for hydraulic breakers, pulverizers, and grapples. An example is a city-wide demolition project where excavators with this pump systematically dismantled old industrial buildings, the pump's consistent pressure delivery allowing for efficient and safe operation.

Road Building & Infrastructure:

Excavators are crucial for preparing sites, digging culverts, and shaping embankments in road construction. The pump's durability ensures it can withstand prolonged use in varying terrain and weather conditions. On a new highway construction, machines fitted with these pumps worked around the clock, showcasing their endurance and vital role in large-scale infrastructure development.

Installation & Maintenance: Common Issues & Solutions

Proper installation and regular maintenance are crucial for the longevity and optimal performance of your K3V112DTP-9T8L-14 hydraulic pump.

Common Issues:

Loss of Power/Slow Operation: Often indicates internal wear, low hydraulic fluid level, or a clogged filter.

Overheating: Can be caused by contaminated fluid, insufficient fluid, or internal leakage.

Excessive Noise: May signal air in the system, cavitation, worn bearings, or misaligned components.

Oil Leaks: Typically due to damaged seals, loose fittings, or cracked casings.

Contamination: Dirt and debris in the hydraulic fluid can cause premature wear and system failure.

Solutions:

Regular Fluid Checks: Ensure hydraulic fluid levels are always at the recommended mark and fluid is clean. Replace fluid and filters according to manufacturer's schedule.

System Flushing: Periodically flush the hydraulic system to remove contaminants.

Seal & Hose Inspection: Routinely inspect all seals, hoses, and fittings for signs of wear, cracks, or leaks. Replace immediately if damaged.

Preventive Maintenance: Adhere strictly to the excavator's maintenance schedule. This includes checking pressure settings, inspecting pump mounting, and lubrication.

Professional Inspection: For complex issues or unexplained symptoms, consult with certified hydraulic technicians for diagnosis and repair to prevent further damage.

By proactively addressing these areas, you can significantly extend the life and efficiency of your K3V112DTP-9T8L-14 hydraulic pump, ensuring your excavator remains productive.

English

English português

português Français

Français