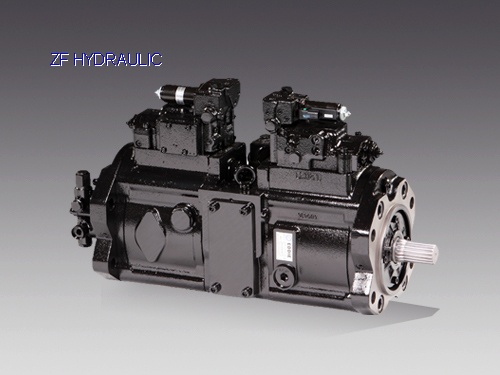

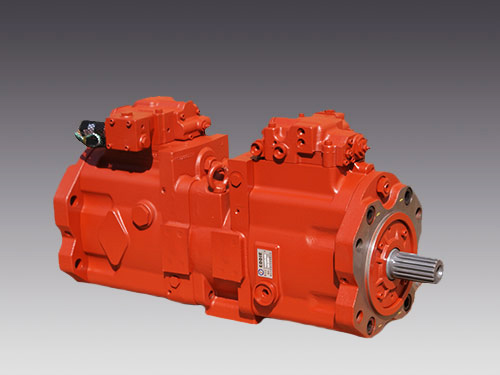

Product Overview

The Main Pump K3V112DTP-YT6K-17T Excavator Hydraulic Pump is a high-performance, critical component designed specifically for Kobelco SK210 and SK200 series excavators. As a core part of the hydraulic system, this axial piston pump ensures the powerful and precise operation of your heavy machinery, delivering the necessary fluid power for demanding tasks on any job site.

Manufactured to meet stringent quality standards, this K3V112DTP pump variant is engineered for durability, efficiency, and seamless integration with your Kobelco equipment, ensuring your excavator operates at peak performance.

Installation & Maintenance: Common Issues & Solutions

Proper installation and regular maintenance are crucial for the longevity and optimal performance of your hydraulic pump. Here are common issues and their solutions:

1. Fluid Contamination

Issue: Dirt, water, or debris entering the hydraulic fluid. This is a leading cause of premature wear, reduced efficiency, and system failure.

Solution: Regularly inspect fluid for discoloration or particles. Follow manufacturer's recommendations for fluid change intervals. Use high-quality filters and replace them promptly. Ensure clean storage and handling of hydraulic fluid.

2. Leakage

Issue: Visible fluid leaks around seals, hoses, or fittings. Leads to fluid loss, reduced pressure, and potential environmental hazards.

Solution: Conduct routine visual inspections for damp spots or puddles. Tighten loose fittings, replace worn or cracked hoses, and renew damaged seals immediately. Consider UV dye leak detection for subtle leaks.

3. Unusual Noise or Vibration

Issue: Whining, knocking, rattling, or excessive vibration from the pump. Often indicates aeration (air in fluid), cavitation (vapor bubbles), worn bearings, or misalignment.

Solution: Check hydraulic fluid level and ensure suction lines are not restricted. Inspect for air leaks in the suction line. Verify pump alignment and mounting. Replace worn bearings and internal components as needed. Maintain proper fluid viscosity.

4. Loss of Pressure / Reduced Performance

Issue: Machine operates slowly, lacks power, or struggles with heavy loads. Can be caused by internal leakage, worn components, or pump inefficiency.

Solution: Inspect for internal and external leaks. Check relief valve settings. Evaluate pump output pressure and flow with diagnostic tools. Worn pistons, barrels, or control components may need replacement.

5. Overheating

Issue: Hydraulic fluid temperature is excessively high. Can degrade fluid quality, damage seals, and lead to pump failure.

Solution: Ensure adequate fluid level and correct fluid type/viscosity. Check cooling system (cooler, fan) for blockages or malfunctions. Verify proper lubrication and minimize excessive friction. Address any issues causing fluid contamination or flow restriction.

Always refer to your excavator's service manual for detailed, model-specific maintenance procedures and troubleshooting guides.

English

English português

português Français

Français