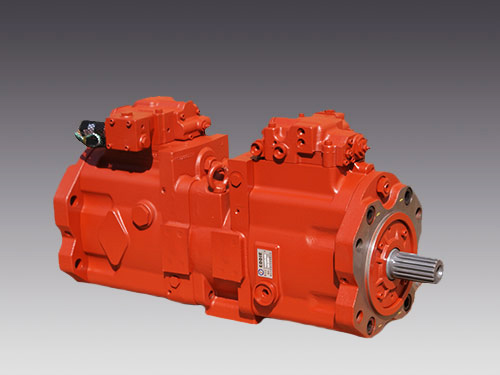

F5VP2D36 Hydraulic Pump: Precision Power for Demanding Applications

The F5VP2D36 Hydraulic Pump is a high-performance, variable displacement axial piston pump designed to deliver exceptional reliability and efficiency in a wide range of hydraulic systems. Engineered for precision control and robust operation, this pump is an ideal choice for demanding industrial and mobile applications where consistent power and energy savings are paramount.

Product Parameters

Model: F5VP2D36

Pump Type: Variable Displacement Axial Piston Pump

Displacement: 36 cc/rev (cubic centimeters per revolution)

Maximum Operating Pressure: Up to 280 bar (4060 psi)

Maximum Flow Rate: (Dependent on RPM, typically up to 100 L/min at rated speed)

Control Type: Pressure Compensated, Load Sensing (specific control options may vary)

Mounting: ISO Standard Flange (e.g., SAE 2-bolt, SAE A, B, C – please verify specific configuration)

Rotation: Clockwise/Counter-clockwise (reversible options available)

Fluid Compatibility: Mineral Oil, Phosphate Ester, Water Glycol (check specific seals)

Key Advantages and Selling Points

High Efficiency: Optimized design minimizes energy loss, leading to lower operating costs and reduced heat generation.

Precise Control: Variable displacement capability allows for fine-tuning of flow and pressure, ensuring accurate system response.

Robust Durability: Constructed with high-quality materials and precision engineering for extended service life in harsh environments.

Low Noise Operation: Engineered to minimize noise levels, contributing to a more comfortable working environment.

Compact Design: Space-saving footprint allows for easier integration into various machinery designs.

Versatile Applications: Adaptable to a broad spectrum of hydraulic systems due to its flexible control options.

Applicable Equipment and Application Scenarios

The F5VP2D36 Hydraulic Pump is widely applicable in a variety of machinery requiring reliable and efficient hydraulic power. Its robust design and precise control make it ideal for:

Construction Machinery: Excavators, bulldozers, wheel loaders, and concrete pumps.

Case Study: In a large-scale infrastructure project, an excavator equipped with the F5VP2D36 pump demonstrated superior digging force and faster cycle times compared to machines with fixed displacement pumps. The pump's load-sensing capabilities allowed for precise power delivery, reducing fuel consumption during varied digging conditions.

Agricultural Equipment: Tractors, harvesters, and irrigation systems.

Case Study: A modern combine harvester utilized this pump for its header control and threshing functions. The precise flow control enabled by the F5VP2D36 minimized grain loss and optimized harvesting efficiency, especially in fields with varying crop densities.

Industrial Automation: Machine tools, presses, and material handling systems.

Case Study: In a high-speed stamping press, the F5VP2D36 pump provided the rapid response and consistent pressure required for precise metal forming. Its energy-saving features also contributed to a significant reduction in the factory's overall power consumption.

Mining Equipment: Drill rigs, conveyor systems, and crushing machinery.

Case Study: A deep-hole drill rig operating in a remote mine benefited from the pump's durability and ability to withstand extreme conditions. The consistent power delivery ensured uninterrupted drilling operations, crucial for meeting production targets.

Marine Applications: Steering systems, winches, and auxiliary power units on vessels.

Case Study: A fishing trawler upgraded its winch system with the F5VP2D36, resulting in smoother and more controlled net deployment and retrieval. The pump's robust construction proved invaluable in the harsh marine environment.

Related Similar Products

For applications requiring different displacements or specific control features, we offer a range of similar high-quality hydraulic pumps:

F5VP2D22 Hydraulic Pump: A smaller displacement version (22 cc/rev) ideal for lighter duty applications such as compact loaders, small agricultural machinery, and light industrial presses.

F5VP2D45 Hydraulic Pump: A larger displacement version (45 cc/rev) suitable for heavier machinery like large excavators, heavy-duty mobile cranes, and large injection molding machines, where higher flow rates are required.

F5VP2D Series with Electronic Control: These pumps offer advanced electronic control options (e.g., proportional pressure control, flow limiting) for sophisticated systems found in robotics, highly automated manufacturing lines, and precision testing equipment.

Fixed Displacement Gear Pumps (e.g., F5G Series): While the F5VP2D36 is a variable piston pump, for simpler, cost-effective systems where constant flow is acceptable, fixed displacement gear pumps are suitable. They are often used in power steering systems, lubrication systems, and small auxiliary circuits.

Installation and Maintenance: Common Issues and Solutions

Proper installation and regular maintenance are crucial for the longevity and optimal performance of your F5VP2D36 Hydraulic Pump. Here are some common issues and their solutions:

Issue: Excessive Noise/Vibration

Cause: Air cavitation, contaminated fluid, misaligned coupling, worn bearings, or improper mounting.

Solution: Check fluid level and quality (ensure no air ingress), flush and replace fluid if contaminated, inspect and re-align coupling, check and replace worn bearings, ensure pump is securely mounted.

Issue: Overheating

Cause: Low fluid level, clogged cooler, undersized reservoir, excessive system pressure, internal leakage, or improper fluid viscosity.

Solution: Top up fluid, clean or replace cooler, ensure adequate reservoir size, check and adjust system pressure, inspect for internal wear, use recommended hydraulic fluid.

Issue: Loss of Pressure/Flow

Cause: Worn internal components (pistons, barrel, swash plate), faulty control valve, air in the system, clogged inlet filter, or external leakage.

Solution: Inspect and replace worn internal parts, troubleshoot and repair/replace control valve, bleed air from the system, clean/replace inlet filter, identify and repair external leaks.

Issue: External Leaks

Cause: Damaged seals (shaft seal, O-rings), loose fittings, cracked housing, or excessive pressure.

Solution: Inspect and replace damaged seals, tighten all fittings to specification, replace cracked components, ensure system pressure is within limits.

General Maintenance Tips:

Regularly check hydraulic fluid level and quality.

Adhere to recommended fluid change intervals.

Keep filters clean and replace them as per manufacturer guidelines.

Inspect hoses, fittings, and seals for wear or damage.

Ensure proper alignment of pump and motor.

Periodically check system pressure settings.

English

English português

português Français

Français